Back in September, our Vacheron Constantin area sales rep emailed one of the Zadoks to ask if I would be able to attend a training with the brand in Geneva, Switzerland the following month.

Let’s see, I thought. Do I want to go on an all expenses paid trip to Geneva with one of the oldest and most respected watch manufactures in the history of watchmaking to visit their headquarters? As part of an exclusive group of only five other salespeople from big time retailers in the North American market? Switzerland with Vacheron Constantin? Oh gee, I don’t know. I’ll have to think about it.

NOT.

I realized I’d be about five months pregnant during the trip, so I immediately called my OB to make sure I was okay to travel. I knew I would be, but I also knew my husband would be very unhappy if I accepted the invitation without talking to the doctor first. As soon as I got the go-ahead, I emailed back to accept the invitation and texted my husband to let him know I’d be jetting off to Switzerland with Vacheron Constantin for a week while carrying our unborn child. He was cool with it.

If you’ve never heard of Vacheron Constantin, it’s because they only make about 25,000 watches per year. Compare this to Rolex, which produces more than 800,000 per year. Vacheron Constantin doesn’t do any marketing with celebrities, either. It is one of the watchmaking maisons under the Richemont group, which also owns Cartier, Montblanc and Jaeger-LeCoultre, to name a few. Vacheron Constantin was founded in 1755 in Geneva and has had uninterrupted production since then. No other manufacture can make the same claim. Think about it– that’s older than the United States. They specialize in belle haute horlogerie, or beautiful high watchmaking. After my trip, I understand better than ever what that actually means.

First Impressions

Geneva in autumn is gorgeous. The leaves are turning, the weather is chilly but not too cold, and the sky is overcast for the most part. Coming from the tail end of a Houston summer, I loved it.

It’s the kind of city where no one jaywalks and everything runs on time. Plus, they speak French, so I got to practice.

Day 1: Let the Training Begin

Our first full day began at the Vacheron Constantin manufacture and administrative headquarters in Plan-les-Ouates, which is about a 30 minute drive outside the city center. Designed by famed architect Bernard Tschumi, the building was completed in 2005 and is a sight to behold.

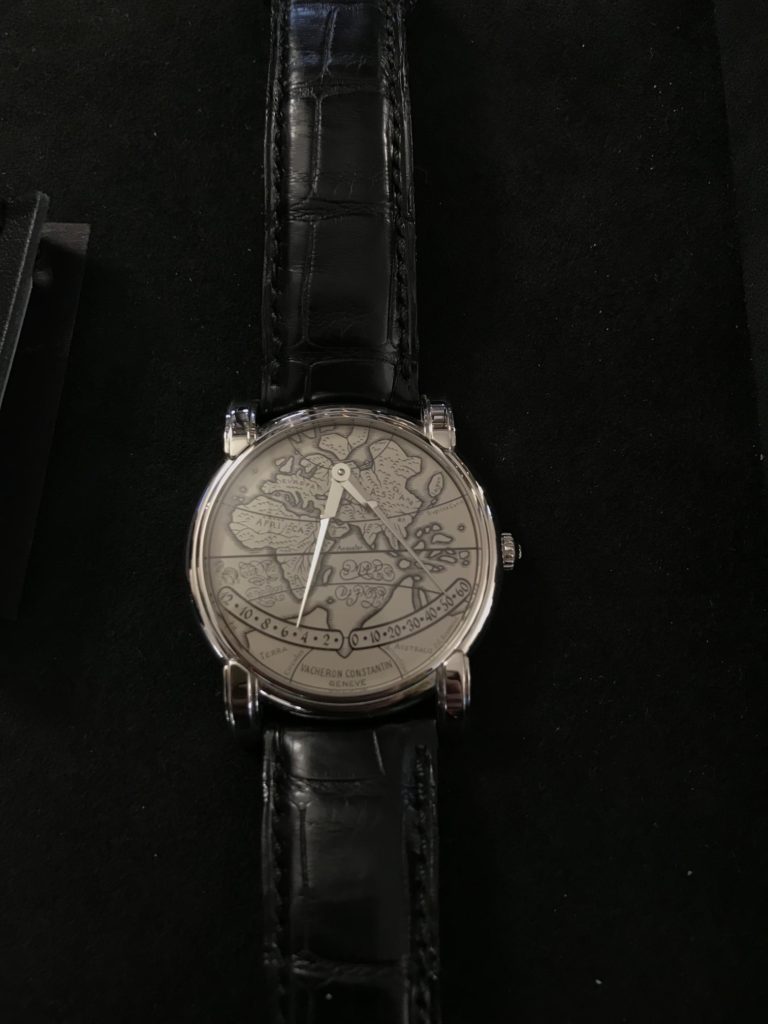

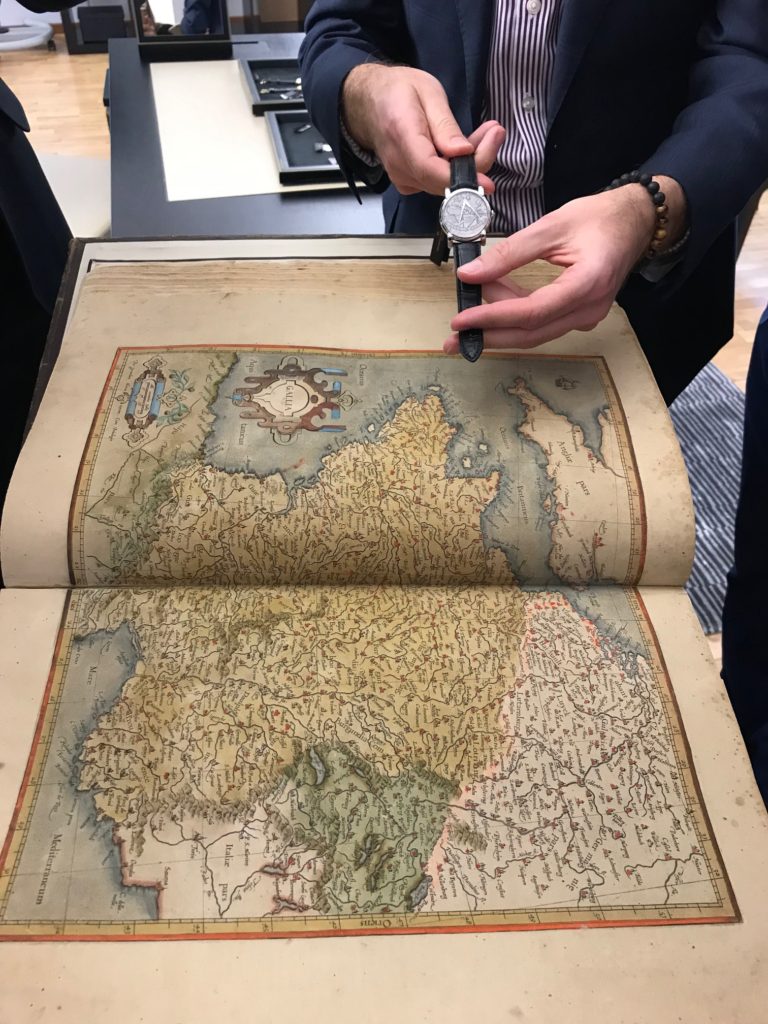

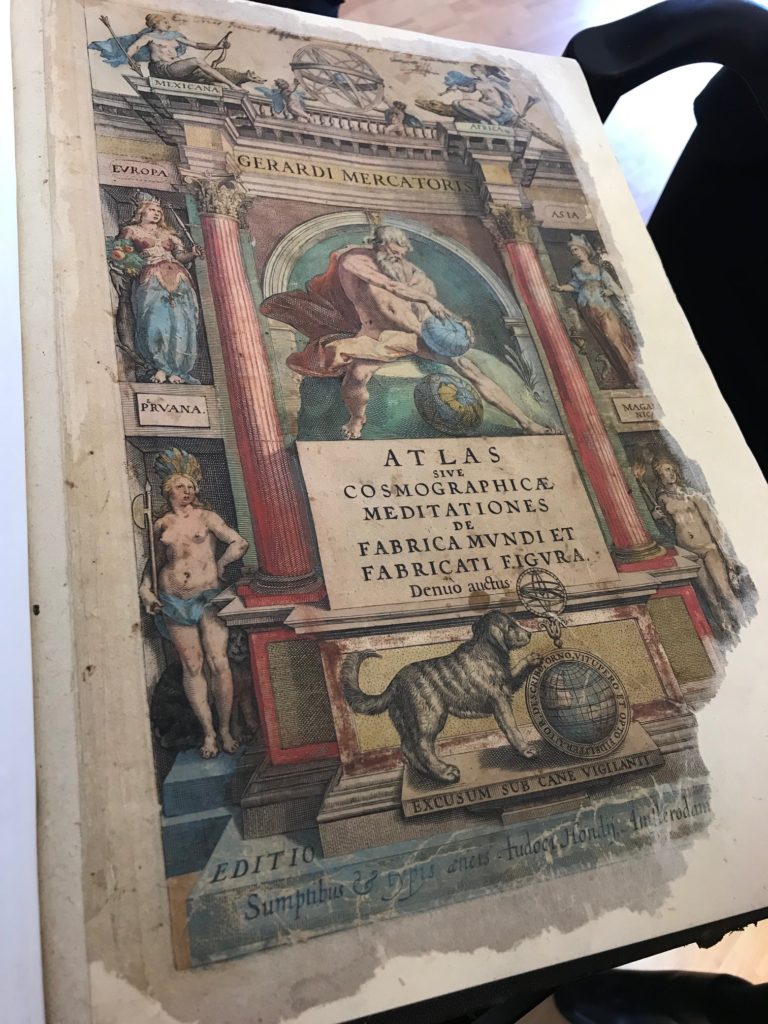

This day started with a general reintroduction to the maison’s history and a look at some heritage pieces from the archives. We saw some truly incredible things. My favorite was the original watch inspired by Gerard Mercator’s 16th century atlas.

Vacheron Constantin acquired the atlas itself at auction many years later, so we got to see that, too! Mercator created the term “atlas” to describe a collection of maps, if that gives you any idea of his importance in the world of cartography.

We also got to see a watch from 1921 that inspired the design of a watch I sold last year!

The watch in the center is the original.

A beautiful Vacheron Constantin watch I sold last year. This is the Historiques Americain 1921 in platinum.

In the afternoon, we got to practice putting together a mechanical watch movement. I didn’t have a knack for this, but I managed to finish. It was an interesting exercise and I was glad I got to try it out. I should note that it was not a Vacheron Constantin movement!

That night, we ate our weight in fondue at Hôtel de Ville. If you ever find yourself in Switzerland while not drinking, our waiter suggested an excellent pairing for me. (I had finished my sad one-third of a glass of wine and was looking dejected, which prompted him to make the suggestion). It was a Swiss sparkling apple juice and it did indeed go very well with the cheese. I regret not bringing a few bottles home for the holidays. Martinelli’s apple cider is not the same.

Day 2: Journey Into the Vallée de Joux

Day two was my favorite. I woke up with a raging sore throat and felt very tired, but chose to ignore that. We boarded our shuttle and headed toward Le Brassus, a town in the Vallée de Joux about an hour and a half from central Geneva. It was otherworldly.

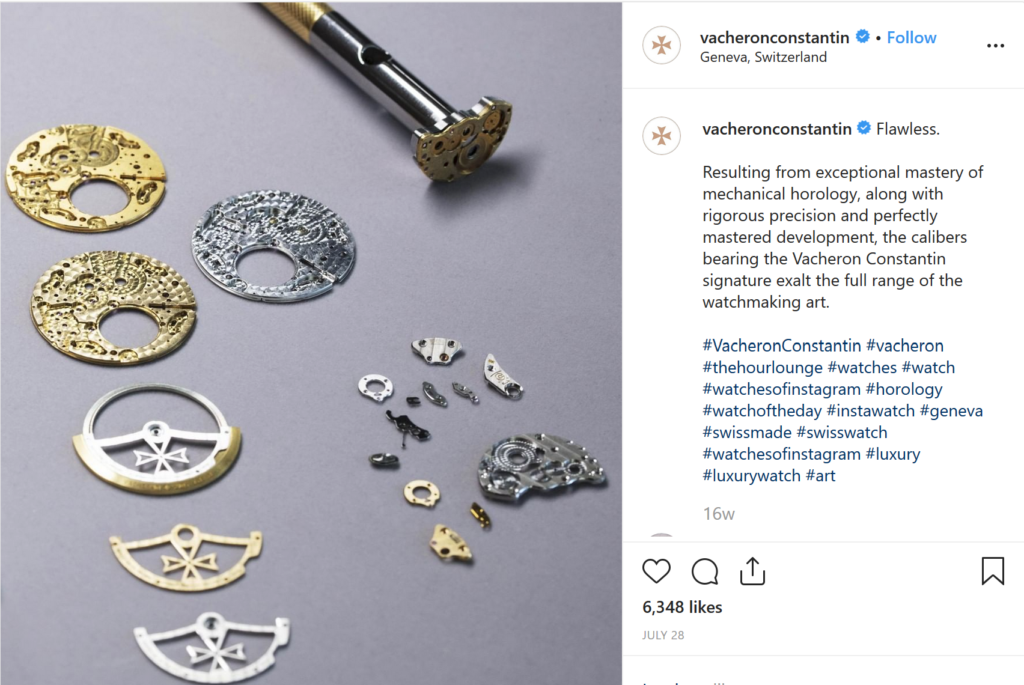

The Vacheron Constantin manufacture in Le Brassus handles watch component production and finishing. Before assembly by a watchmaker, each component is hand decorated to extremely strict aesthetic standards set by the maison. Most of our day focused on this, and we got to observe the people doing it in action. Imagine your entire workday, work week, work life devoted to engraving one tiny part of a watch movement, for example. It takes an unbelievable amount of concentration and skill.

I got to try my hand at a couple, including perlage, also known as circular graining. This requires pressing a tiny whirring engraver onto a movement plate to create overlapping circles. It’s vital to maintain the same amount of pressure when pulling down each time and just as important keep the circles perfectly spaced. I did okay!

I also did some chamfering, which is beveling a perfect 45 degree angle onto any edge that requires it. There is no way to measure the angle; you only know it’s right from the way the light reflects. Having done some bench jewelry work in the past, I was better at this. I’m still waiting for my job offer, though. Any day now!

Giving it a try.

Checking my work.

We made the drive back to Geneva and I passed out most of the way back, as did everyone else. When we got back, we made a visit to the Vacheron Constantin Geneva boutique, conveniently located right next to our hotel. It was immaculate and beautiful. Now that I mention it, I don’t think I saw a speck of dust anywhere the entire time I was in Switzerland.

Boutique entrance

Boutique second floor

Watchmaker station

Strap display

By the end of the day I felt like death warmed over, and in addition to the sore throat, I had the sniffles. So after dinner I went to bed early, excited for our last day of training.

Day 3:

Our last day brought us back to the headquarters in Plan-les-Ouates. My nose was running like a faucet by now, and any hope of a quick recovery had flown out the window, but I didn’t have a fever so I was determined to make it through the last day. I knew I had a run-of-the-mill cold, so I just tried my best to pay attention while sanitizing my hands a lot.

Despite my faucet nose, it was a really nice day. We visited the Métiers d’Art workshop, where we got to see enameling and hand engraving of some specialty pieces. The gem setter was on vacation, unfortunately, so we didn’t get to see any watches being set with diamonds or gemstones. (The Swiss get something like 40 vacation days a year, so it was inevitable that someone would be gone during these tours– good for them!) We couldn’t take photos of the engraving, but I was able to capture this nifty wall of enamel colors.

We also visited the design studio, where we got to learn about the entire design process, from creative inspiration to 3D-printed prototypes to final color selection. No photos were allowed here, for obvious reasons. I appreciated this peek behind the curtain in particular. Most watch trainings primarily focus on brand history and watch movements with maybe a minute or two devoted to design inspiration, so to get a detailed explanation of the creative process surrounding aesthetics was interesting.

At the end of the day, we had a mini-graduation of sorts. Hugo Castro, the international training project manager for Vacheron Constantin, presented each of us with a certificate of completion.

I had such an amazing experience in Switzerland with Vacheron Constantin and cannot thank the training team enough. It was better than I could have dreamed. I understand so much better the time and effort put into creating these amazing timepieces. I wish I hadn’t gotten sick, but I have no regrets.